[Creative Originality], the concept of S.K. Company Limited,

is a motto of all our employees.

S.K. ASIA CO.,LTD.

Company Profile

Always keeping our original intention in mind, we will do our best to answer customer’s needs and become a trustworthy partner.

Please give S.K. Asia Company Limited your warm support. We sincerely wish all your companies further progress.

| Website | http://www.skasia.co.th |

| Establish Date | August 2008 |

| Capital | 25,750,000 Baht |

| Parent Company | S.K. HOLDINGS CO., LTD. |

| Shareholder | S.K. HOLDINGS CO., LTD. |

| Employee | 24 Persons (November 2018) |

| Account Period | March |

| Parent Company Location | 4F,YUTAKA BLDG. 2-6-28, MINAMISENBA, CHUO-KU, OSAKA 542-0081 TEL:(06)6262-1357 FAX:(06)6261-1015 |

| Company Name | S.K. ASIA CO., LTD. |

| Representative Person | President : Mr. Shoho Kaneishi |

| Business Description | Sales Import-Export of Used injection Molding Machines and repairing |

| Product Line | New and used Injection Molding Machines and accessories |

About Us

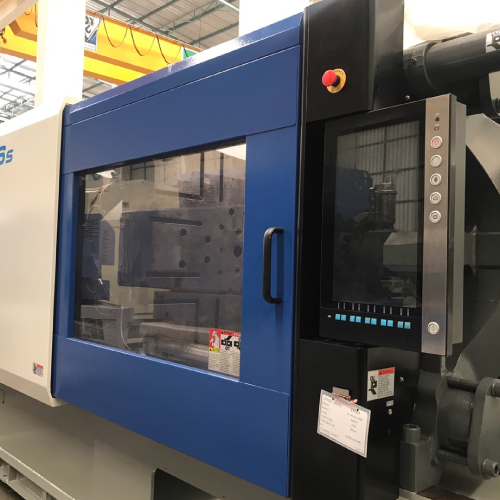

Sales of Used injection Machine

■ Sales of Used Injection Machine and new Machine ■ Maintenance・Recondition ■ Purchases of Used Injection Machine

-

Japanese Maker

Every machine is made by Japanese manufacturers reliable and known worldwide. -

Testing a Machine

All machines are fully maintained and tested before delivery to the customer. Even customers can bring their own mold and test it with the machine at SK ASIA. -

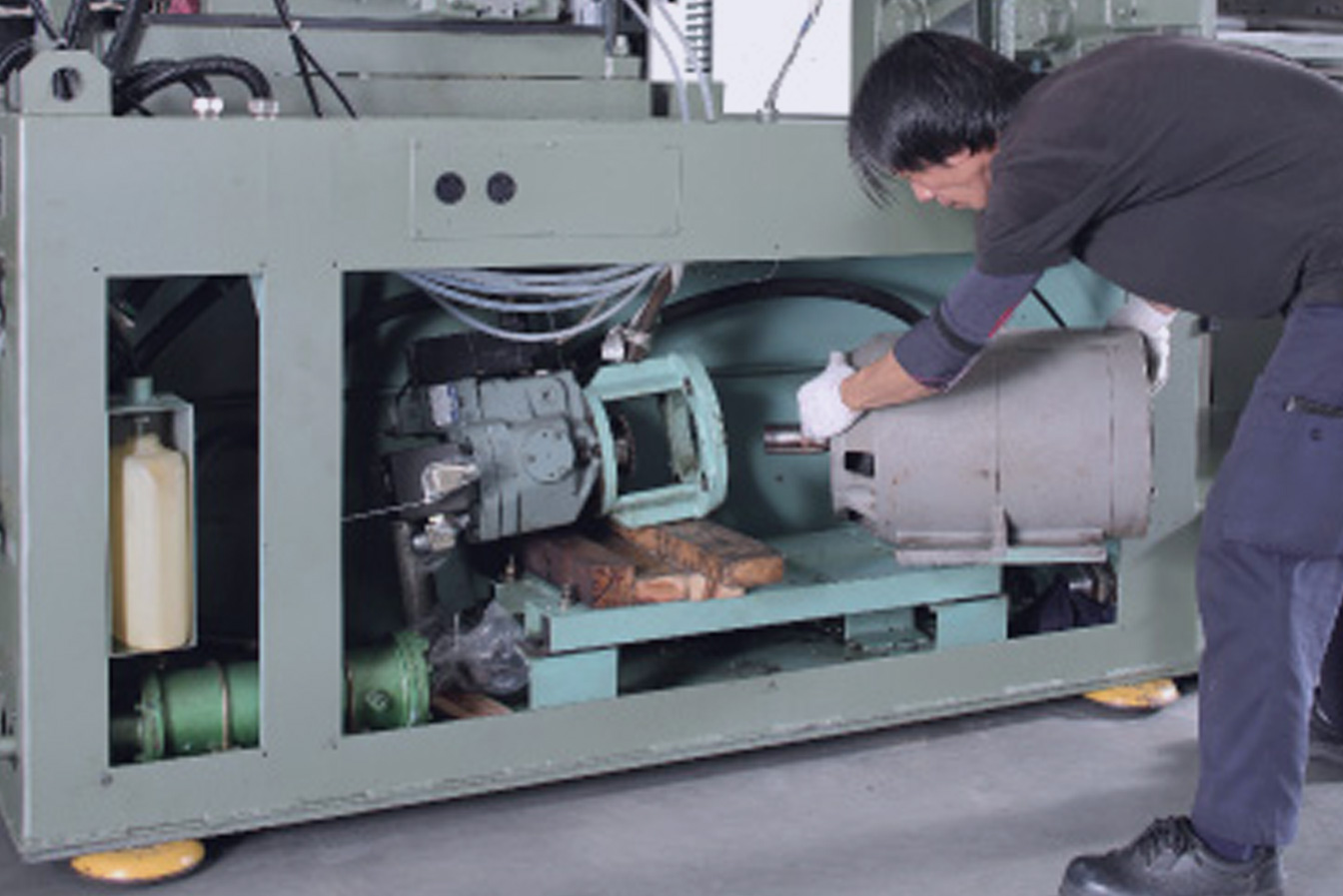

Japanese Engineer

Our accomplished and reliable engineer will take great care of your machines. Please feel free to ask any questions about machines.

Latest Used Machine

We always have 100 USED INJECTION MACHINES in stock!!!

-

01

MAKER : MITSUBISHI

MODEL 1050em-160 CLAMPING FORCE 1050 tons YEAR 2003 SCREW 105 mm CONTROLLER MAC-VIII TYPE HYBRID -

02

MAKER : JSW

MODEL J55AD-60H CLAMPING FORCE 55 tons YEAR 2012 SCREW 280 mm CONTROLLER SYSCOM3000 TYPE ELECTRIC -

03

MAKER : SUMITOMO

MODEL SR50D-C75 (VERTICAL) CLAMPING CLAMPING FORCE 50 tons YEAR 2006 SCREW 16 mm TYPE ELECTRIC -

04

MAKER : JSW

MODEL J180ELIII CLAMPING FORCE 180 tons YEAR 2002 SCREW 46 mm CONTROLLER SYSCOM2000 TYPE ELECTRIC -

05

MAKER : JSW

MODEL J350AD-890H CLAMPING FORCE 350 tons YEAR 2007 SCREW 66 mm CONTROLLER SYSCOM3000 TYPE All Electric -

06

MAKER : MITSUBISHI

MODEL 1300MMIII-240 CLAMPING FORCE 1300 tons YEAR 2004 SCREW 120 mm CONTROLLER MAC-VI TYPE Hydraulic Type -

07

MAKER : TOSHIBA

MODEL EC60C-1.5A CLAMPING FORCE 60 tons YEAR 2005 SCREW 28 mm CONTROLLER VISOR-C10 TYPE All Electric -

08

MAKER : NISSEI

MODEL NEX4000-36E CLAMPING FORCE 180 tons YEAR 2005 SCREW 50 mm CONTROLLER TACT TYPE All Electric -

09

MAKER : TOYO

MODEL SI-350-6S-J450E CLAMPING FORCE 350 tons YEAR 2018 SCREW 68 mm CONTROLLER SYSTEM600 TYPE All Electric

Maintenance/ Recondition Flow Chart

-

- 01

UnloadingUnloading machines from container and truck. -

- 02

CleaningIncluding : machine, oil tank, oil cooler, oil filter, motor, hopper throat, water jacket, control box, and etc , before test run. -

- 03

1st Test run and Repairing• Take out the screw and check condition before - machine drive.

- • Check machine condition by dry test, and diagnose the defected or damaged parts.

- • Repair or replace defected and damaged parts

- (if it is necessary)

-

- 04

ReconditionIt is not overhaul it is the S.K. ASIA style maintenance, and it calls RECONDITION that include Replace sealing - A) Pump shaft seal

- B) Injection unit cylinder (back and forward)

- C) Injection ram cylinder (plasticization)

- D) Ejector cylinder seal (if it is necessary)

- E) Clamp cylinder seal (if it is necessary)

- F) Hydraulic Valve seal (if it is necessary)

- • Replace hydraulic hose (when it has oil leak or damage)

- • Replace cooling water hose

-

- 05

RepaintingRepainting in original color or customer's request. -

- 06

2nd Test runRecheck the machine condition after painting and recondition. Make sure that all parts are in the right position and operation goes normally. -

- 07

Demonstrate to the customer• Show the actual condition of the machine to the customer and ensure the movement of machine

and appearance- • Even customer can bring own mold, material, and test drive with machine in S.K.ASIA. Our engineer will

- support to you.

- *However this is the test for machine condition, and we cannot guarantee the quality of products.

-

- 08

Final Test driveMake sure that machine is good condition and work properly again before delivery to the customer -

- 09

Delivery and InstallationOur reliable transportation company and installation company will take care of your machine till the installation will be completely. - *However, floor foundation construction, electric, water work and air supply construction should be

customer side. -

- 10

Test run at the customer sideAfter all construction and installation done, our engineer will start up the machine and support your staff to operate the machine at your factory.

Inquiry

Sale Inquiry Injection Molding Machine

- S.K. ASIA CO.,LTD.

-

AMATA CITY CHONBURI INDUSTRIAL ESTATE - 700/270 Moo 1 Tambol Bankao, Amphur Panthong, Chonburi 20160 Thailand